Tags

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

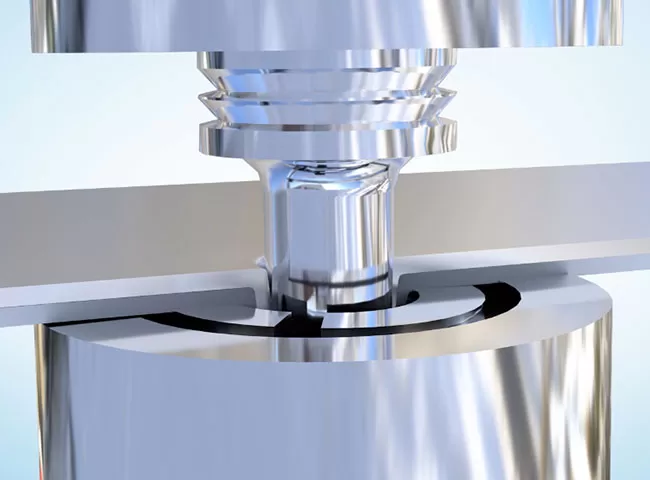

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

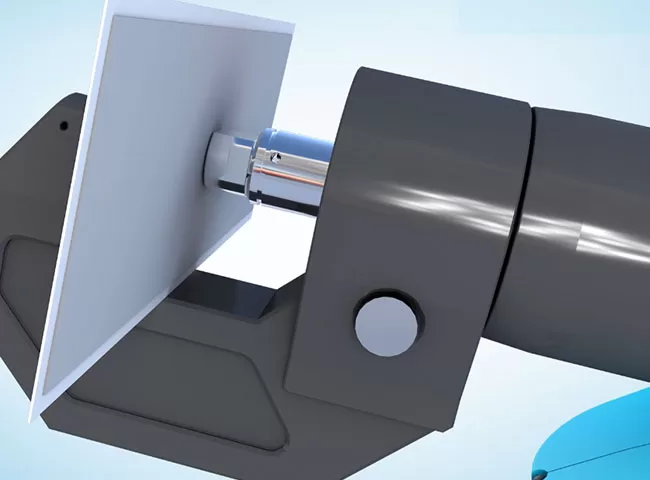

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

Unveiling the Technology Behind Self-Piercing Riveting Guns

Self-piercing riveting (SPR) is used extensively in many modern manufacturing applications.

Solid Rivets As Timeless Fasteners for Reliable Connections

Solid rivets are mechanical fasteners used to join two or more pieces of material together permanently.

How Self-Piercing Rivet (SPR) Guns Boost Productivity ?

Questok self-piercing rivet (SPR) gun is a specialized tool designed to join or fasten materials together using self-piercing rivets.

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

Solid Rivet Guns in Vehicle Manufacturing and Repair

Solid rivet guns, also known as pneumatic riveters, are designed to efficiently and effectively drive solid rivets into metal structures.

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

Questok Electric Rivet Guns Service New Energy and High-End Vehicles Repairing

With the increasing global environmental requirements, energy conservation and emissions reduction have become the new slogans. The forefront of environmental reform lies in the automotive field, specifically in reducing carbon dioxide emissions.