The Application and Maintenance of Self-Piercing Rivet Guns

With the continuous development of modern manufacturing industry, the application of self-piercing rivet guns in different fields has gradually become a key factor in promoting efficiency and improving quality.

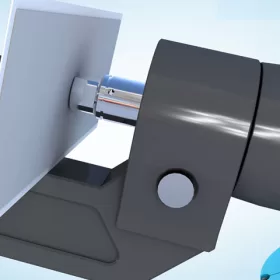

Self-piercing rivet guns are specialized tools used to join materials by driving rivets through them. Unlike traditional riveting methods, self-piercing rivet guns can pierce and join materials in a single operation. This innovative approach not only expedites the manufacturing process but also enhances overall efficiency.

This article will take an in-depth look at the specific applications of self-piercing rivet guns in automotive manufacturing and aerospace, and explore the necessity of maintenance to keep this powerful tool functioning properly.

Application of Self-Piercing Rivet Guns

In modern manufacturing, self-piercing rivet guns, with their unique design and efficient working principles, have become a key tool for improving efficiency and quality. Their wide range of applications in different fields, especially in automotive manufacturing and aerospace, demonstrate their excellent performance and versatility.

Self-Piercing Rivet Guns in Automotive Manufacturing

Automobile manufacturing is one of the typical areas where self-piercing rivet guns are widely used. This tool plays a key role in automobile manufacturing, promoting the modernization and efficiency of the manufacturing process, mainly in the following aspects:

1. Material Connection

Self-piercing rivet guns have brought innovation to material joining in automobile manufacturing through their unique working principle, which is to complete the penetration and joining of materials in one operation. Traditional riveting methods often require multiple steps, including tedious operations such as pre-drilling holes.

In contrast to conventional methods, self-piercing riveters operate with remarkable speed and efficiency, enabling the formation of robust rivets on materials in a seamless fashion. This not only bolsters the strength of the connection but also serves to significantly simplify the entire joining process.

This efficient connection method not only enhances the structural integrity of the assembled materials but also reduces the complexity of the manufacturing process, injecting a more convenient and reliable process into automobile manufacturing.

2. Efficiency Improvement

With their efficient operating speed, self-piercing rivet guns have achieved a significant improvement in production efficiency. Compared with traditional riveting methods, self-piercing rivet guns complete material penetration and connection in one operation, greatly improving production efficiency.

For large-scale automotive manufacturing, by eliminating complex and time-consuming steps such as pre-drilling holes, SPR rivet guns not only speed up the assembly process but also significantly reduce the time required for each manufacturing cycle, allowing manufacturers to meet market demand more flexibly. In addition, the reduction in production time directly contributes to a decrease in production costs, enabling manufacturers to operate with increased cost-efficiency.

3. Lightweight Design

In automobile manufacturing, self-piercing rivet guns help achieve lightweight designs. By using high-strength riveting materials, self-piercing rivet guns help manufacturers reduce the weight of entire vehicles. Less weight means less energy consumption, which can improve a car’s fuel efficiency.

Vehicles built with self-piercing rivet guns not only consume less fuel but also help lower emissions, making them more environmentally friendly. At a time when environmental considerations are paramount, the collaboration between handheld self-piercing rivet guns and high-strength materials becomes a crucial enabler of environmentally friendly vehicle practices.

Self-Piercing Rivet Guns in Aerospace

In the aerospace industry, self-piercing rivet guns also play an indispensable role, bringing transformative capabilities to complex processes of aircraft assembly and structural integrity. Their applications are reflected in the following aspects:

1. Structural Assembly

The aerospace field has strict requirements on structural strength and lightweight. Self-piercing rivet guns support the assembly of complex structures through efficient connection methods. In complex aircraft and spacecraft designs, self-piercing riveters can quickly and accurately join various materials to ensure the solidity of the overall structure.

By streamlining the assembly process, self-piercing rivet guns’ high-speed joining process helps reduce assembly time, allowing aerospace projects to move forward more efficiently.

2. Production Efficiency

In the manufacturing of aircraft and spacecraft, the high speed and high efficiency of electric self-piercing rivet guns are key factors to ensure that projects proceed as planned. In the manufacture of aircraft and spacecraft, the rapid operation of these tools can significantly shorten the assembly cycle and ensure that the entire project can be delivered on time.

The efficiency of self-piercing rivet guns not only improves overall production efficiency but also provides time flexibility for aerospace engineering, making project management more controllable.

3. Material Adaptability

The aerospace industry usually uses high-strength and special alloy materials, requiring connection tools to have a high degree of material adaptability. Self-piercing rivet guns are able to adapt to and handle these complex material connections due to their design flexibility and powerful penetration.

Whether it is titanium alloy, aluminum alloy or other high-strength materials, handheld self-piercing rivet guns can complete efficient connections without losing connection quality. This provides greater design flexibility for aerospace engineering, giving engineers more freedom to choose the materials that best suit the needs of the project, thus promoting innovation and improving the overall quality of aerospace structures.

Maintenance of Self-Piercing Rivet Guns

Although self-piercing rivet guns play an important role in different industries, their long-term reliability and efficiency cannot be achieved without proper care and maintenance. Proper care and maintenance ensure stable operation of SPR rivet guns and also extend their service life. The following are important practices related to the care and maintenance of self-piercing rivet guns:

Basic Maintenance

Users should perform basic maintenance regularly, including cleaning the tool surface. This is not only to keep the appearance tidy but more importantly to prevent impurities from entering key components and affecting operation. Any dirt or foreign matter that accumulates on the surface of self-piercing rivet guns can cause increased friction or prevent proper operation, so keeping them clean is a top maintenance priority.

At the same time, in basic maintenance, providing necessary lubrication to key components cannot be ignored. Lubrication reduces wear and friction, ensuring efficient operation of the self-piercing rivet gun.

Regular Maintenance

In addition to daily basic maintenance, regular maintenance is an important part of ensuring the long-term reliability of the self-piercing rivet gun. This includes a more comprehensive inspection of the entire tool system to ensure all components are functioning properly. For electric or pneumatic systems, regularly inspect key components such as motors, transmissions and compressors to make sure they are not showing abnormal wear or damage.

This kind of regular maintenance is a preventive measure that helps detect and repair problems in time before they occur, reducing the risk of sudden failures and ensuring the continuity and reliability of the production line.

Most importantly, users should follow the maintenance guidelines provided by the manufacturer to ensure that maintenance operations are performed according to best practices to extend the life of the tool and maintain its performance.

In Conclusion

The widespread use of self-piercing rivet guns in multiple industries, including automotive manufacturing and aerospace, demonstrates their superior performance in driving efficiency and improving quality.

In the field of automobile manufacturing, self-piercing rivet guns have become the first choice of manufacturers for their excellent performance and efficient connection methods. Not only can the penetration and connection of materials be completed in one operation, but it also plays a key role in the lightweight design of the car body. By using SPR rivet guns, automakers can achieve a more precise and faster production process, improving overall manufacturing efficiency.

In the aerospace field, its efficient structural assembly, improved production efficiency and adaptability to various complex materials have made the self-piercing rivet gun an indispensable key factor in aerospace projects, contributing to the safety and performance of aircraft. Reach new heights.

To keep this powerful tool running properly, users should carefully follow the manufacturer’s maintenance guidelines and perform regular maintenance to ensure it continues to play a critical role in the manufacturing field. Today, in the continuous pursuit of technological innovation, self-piercing rivet guns, as an important tool in the manufacturing industry, will continue to demonstrate their unique application value in various fields.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]