Fast Assembly and Repair With Cordless Solid Rivet Gun

Table of Contents

Brief Overview of Riveting Tools and Methods

In the evolving landscape of industrial tools, Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications. This tool, emancipated from the constraints of cords and pneumatic hoses, offers unparalleled flexibility, allowing operators to work in remote or confined spaces where traditional riveting tools would falter.

At the heart of the cordless solid rivet gun is its battery technology, typically lithium-ion, renowned for its long life and ability to hold a charge. This ensures that the tool can perform over extended periods without necessitating frequent recharging breaks, thereby optimizing productivity. Modern advancements in battery technology have also significantly reduced the weight of these units, making them less cumbersome and more comfortable for prolonged use.

Designed with ergonomics in mind, these rivet guns feature grips that conform to the natural contours of the hand, minimizing strain and fatigue during operation. This attention to operator comfort is critical, as riveting can be a repetitive and physically demanding task. The ergonomic design, combined with the tool’s balanced weight distribution, enables precise control, ensuring high-quality riveting results.

What Are The Benefits of Cordless Solid Rivert Gun ?

Efficiency and Productivity

Questok cordless solid rivet gun accelerates the assembly process by offering a quicker, more reliable method of installing rivets. Unlike their pneumatic counterparts, these cordless models eliminate the need for air hoses and compressors, which not only reduces setup time but also minimizes clutter and tripping hazards in work areas. Workers can move freely and efficiently, focusing on the task at hand without being tethered to a stationary power source.

Portability and Flexibility

One of the standout features of cordless tools is their portability. Cordless solid rivet guns can be easily transported and used in remote locations where access to power is limited or non-existent. This is particularly beneficial in large construction projects, outdoor applications, or in situations where mobility is a necessity. The ability to move around without dragging along additional equipment (like hoses and generators) streamlines operations and opens up new possibilities for work site layouts.

Technological Advancements

Modern cordless solid rivet guns benefit from advancements in battery technology and motor efficiency. High-capacity lithium-ion batteries provide longer runtimes, allowing for extended periods of use between charges. Additionally, brushless motors offer improved performance and durability, reducing the need for maintenance and increasing the tool’s lifespan. These technological improvements ensure that cordless rivet guns can deliver the power and endurance required to meet the demands of heavy-duty applications.

Ergonomics and Safety

Ergonomics play a crucial role in the design of today’s cordless tools. Solid rivet guns are no exception, with manufacturers focusing on creating lightweight and balanced tools that minimize user fatigue and enhance comfort. This not only boosts productivity but also contributes to safer working conditions. By reducing the physical strain on operators and eliminating the risks associated with cords and hoses, cordless rivet guns help lower the incidence of work-related injuries.

Environmental Impact

Transitioning to cordless tools can also have a positive impact on the environment. By reducing the reliance on pneumatic systems, which require compressors and potentially fossil fuel-powered generators, cordless tools contribute to lower energy consumption. Furthermore, the efficiency and precision of cordless rivet guns can lead to less waste material, further minimizing the environmental footprint of manufacturing and construction activities.

Design and Technological Innovations

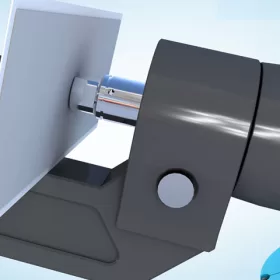

The advent of cordless solid rivet guns has brought about a paradigm shift in riveting technology, introducing a range of key features that enhance performance, efficiency, and user experience. Below is an overview of the pivotal design and technological innovations defining cordless solid rivet guns

Battery Technology and Power Efficiency

Cordless solid rivet guns are powered by advanced lithium-ion batteries, which offer several advantages over traditional power sources. These batteries boast high energy density, providing ample power to drive rivets efficiently without the need for cumbersome cords or air hoses. Moreover, lithium-ion batteries are known for their fast charging capabilities, minimizing downtime and ensuring continuous operation. This power efficiency translates into increased productivity and reduced overall costs, making cordless rivet guns a preferred choice in industrial settings.

Ergonomic Design and User Safety

Another hallmark of cordless solid rivet guns is their ergonomic design, which prioritizes user comfort and safety. These tools are engineered with ergonomic handles and grips, reducing hand fatigue and strain during prolonged use. Additionally, they often feature anti-vibration mechanisms to minimize the risk of repetitive strain injuries. Enhanced safety features such as trigger locks and safety guards further protect users from potential hazards, ensuring a secure working environment. The ergonomic design of cordless rivet guns not only enhances user comfort but also contributes to overall operational efficiency by enabling longer, more comfortable use without sacrificing safety.

Precision and Control in Riveting Operations

Cordless solid rivet guns offer unparalleled precision and control in riveting operations, thanks to their advanced engineering and adjustable settings. These tools allow users to customize parameters such as rivet force and speed, enabling precise control over the riveting process. This level of control ensures consistent results and minimizes errors, leading to higher-quality riveted joints. Moreover, cordless rivet guns often feature built-in mechanisms for monitoring rivet placement and depth, further enhancing accuracy and reliability. The precision and control offered by cordless solid rivet guns make them indispensable tools in industries where accuracy and consistency are paramount.

Comparative Analysis with Traditional Riveting Methods

In comparing cordless solid rivet guns with traditional riveting methods, several key differences become apparent. Traditional pneumatic or manual rivet guns rely on external power sources such as air compressors or manual force, which can limit mobility and require additional equipment setup. In contrast, cordless solid rivet guns offer unmatched portability and flexibility, allowing users to work in various environments without the constraints of cords or air hoses. Moreover, the ergonomic design and precision control of cordless rivet guns often result in faster, more efficient riveting processes compared to traditional methods. Overall, the transition to cordless solid rivet guns represents a significant advancement in riveting technology, offering superior performance, convenience, and safety compared to traditional alternatives.

In sum, the design and technological innovations of cordless solid rivet guns have redefined the riveting landscape, offering unmatched efficiency, precision, and user experience. With advanced battery technology, ergonomic design features, and precise control capabilities, cordless rivet guns have become indispensable tools in modern industrial settings, setting new standards for riveting performance and versatility.

Impact on Industries

Manufacturing

Cordless rivet guns have brought about significant improvements in manufacturing processes, particularly in assembly lines. These tools have streamlined operations by eliminating the need for cumbersome cords and air hoses, allowing workers to move freely and work more efficiently. With cordless rivet guns, workers can complete riveting tasks with greater speed and accuracy, leading to improved production rates and overall throughput. The enhanced portability and ease of use of cordless rivet guns have also reduced setup times and increased the flexibility of assembly lines, enabling manufacturers to adapt quickly to changing production demands. As a result, cordless rivet guns have become indispensable tools in modern manufacturing facilities, contributing to increased efficiency and competitiveness in the industry.

Construction

In the construction industry, cordless rivet guns offer numerous benefits for on-site construction and infrastructure projects. These tools provide construction workers with the flexibility to perform riveting tasks in various locations without the constraints of power cords or air compressors. This increased mobility allows for greater efficiency and productivity, as workers can move freely around construction sites and access hard-to-reach areas with ease. Additionally, cordless rivet guns enable faster assembly and installation of structural components, speeding up construction timelines and reducing overall project costs. By streamlining riveting processes and improving workflow efficiency, cordless rivet guns have become invaluable assets in the construction industry, helping to accelerate project completion and enhance construction quality.

Aerospace and Automotive

In high-stakes environments such as aerospace and automotive manufacturing, precision and reliability are paramount. Cordless rivet guns play a crucial role in these industries by offering precise control and consistent performance, ensuring the integrity of riveted joints in critical components. The advanced technology and ergonomic design of cordless rivet guns enable workers to achieve tight tolerances and meet stringent quality standards required in aerospace and automotive applications. Moreover, the portability and ease of use of cordless rivet guns make them well-suited for use in aircraft and automotive assembly facilities, where space constraints and mobility are important considerations. By providing a reliable and efficient solution for riveting tasks, cordless rivet guns contribute to the production of high-quality, reliable aircraft and vehicles, reinforcing their importance in these industries.

Field Repairs and Installations

When it comes to cordless rivet guns, we would talk about their portability and independence from external power sources, making them ideal for field repairs and installations. Whether performing repairs on machinery, equipment, or structures in remote locations, cordless rivet guns provide workers with the flexibility to work efficiently without the need for access to electricity or compressed air. This portability allows for faster turnaround times on repairs and reduces downtime for equipment and machinery, minimizing disruptions to operations. Additionally, cordless rivet guns enable workers to tackle repair tasks in challenging environments where traditional riveting methods may be impractical or unsafe. As a result, cordless rivet guns have become essential tools for maintenance technicians, repair crews, and service professionals, enabling them to perform their jobs more effectively and efficiently, regardless of location.

Summary

In summary, Questok cordless rivet guns have made a significant impact across various industries, from manufacturing and construction to aerospace, automotive, and field repair applications. By streamlining riveting processes, improving production efficiency, and providing greater flexibility and mobility, cordless rivet guns have become indispensable tools for modern industrial applications, driving productivity, quality, and innovation in the workplace.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]

-

Top Features and Benefits of Universal Self-Piercing Riveting Guns

In the realm of metalworking, precision and efficiency are paramount. Universal self-piercing riveting guns, often referred to as self-pierce riveting guns, embody these qualities, offering remarkable benefits for various applications. These innovative tools feature technologically advanced functions that enhance productivity, reliability, and overall performance, making them indispensable in industries such as aerospace, automotive, construction, and […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]