Rivet Gun FAQ

一.SPR Rivet Gun

1.What thickness of sheet metal can SPR rivets be used on?

- Self-Piercing Rivets (SPR rivets) are a special type of rivet that can join two pieces of sheet metal together without the need for pre-drilling.

- Theoretically, the thickness of sheet metal that SPR rivets can join depends on the length of the rivets and the hardness of the material. Generally, the common range of sheet metal thickness is from 0.8 millimeters to 8 millimeters. However, for particularly thick sheet metal, longer rivets or pre-drilling may be required.

- The riveting direction of SPR rivets is usually one-way. In other words, the rivet is usually inserted from the front of one sheet metal and then pierced out from the back of another sheet metal, achieving the riveting effect. Therefore, during installation, it is necessary to ensure that the relative positions of the sheet metal are correct.

- Different materials have different effects on the riveting ability of rivets. For example, sheet metal with higher hardness may require longer rivets or greater piercing force. Additionally, if the sheet metal has coatings or other surface treatments, it may also affect the riveting effect.

2.What materials can SPR rivets join?

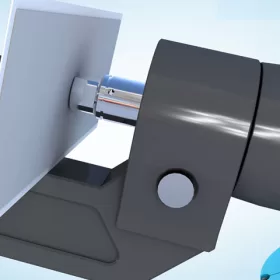

- Metal materials: These are the most common materials for riveting, including steel, aluminum alloys, copper alloys, etc. These materials typically have good strength and durability, suitable for various structural and construction applications. Here is a picture of our QUESTOK rivet gun.

- Non-metal materials: Some non-metal materials can also be joined using self-piercing rivets, such as fiberglass, carbon fiber composites, ceramics, etc. These materials are often used in special applications such as aerospace, automotive manufacturing, sports equipment, etc.

- Coated sheet metal: Self-piercing rivets can join coated sheet metal without damaging the coating, such as steel and aluminum sheets. This is useful for situations where the appearance or specific surface treatment of the sheet metal needs to be maintained.

- It should be noted that for different materials, the models and specifications of self-piercing rivets may vary, and the riveting methods and techniques may also differ. In practical applications, it is necessary to select suitable self-piercing rivets and appropriate self-piercing riveting tools (QUESTOK Shield River SPR rivet gun) according to the specific materials and requirements, and follow the correct installation steps.

3.What are the common quality issues of SPR rivets?

- Loose rivets: Rivet loosening may be caused by various reasons, such as the sheet metal being too thick, improper operation, insufficient rivet length, or material issues. When rivet loosening occurs, the length of the rivet should be checked to ensure it meets the requirements, and propeoperation steps should be followed. Additionally, selecting rivets that meet material requirements is crucial to prevent loosening.

- Fracture: Fractures may result from poor quality rivet materials or improper operation. Excessive force or repeated use of rivets during installation can lead to fractures. To prevent fractures, use rivets that meet quality requirements and follow correct operation steps.

- Improper nail core alignment: Improper alignment of the nail core refers to the axis of the rivet core not being perpendicular to the surface of the sheet metal. This may be due to improper operation during installation or unevenness of the sheet metal surface. To ensure that the nail core is perpendicular to the surface of the sheet metal, appropriate tools should be used during installation, and the sheet metal surface should be leveled.

- Floating rivets: Floating rivets refer to rivets that are not completely embedded in the sheet metal, resulting in exposure or loosening. This may be due to improper operation or excessive thickness of the sheet metal. To prevent floating rivets, select rivets of the appropriate length and follow correct operation steps.

- Insufficient pull-out force: Insufficient pull-out force refers to rivets being easily pulled out when subjected to external force. This may be due to insufficient rivet length or improper operation. To increase pull-out force, longer rivets can be selected, and correct operation steps should be followed.

- Surface defects: Surface defects refer to surface irregularities, bubbles, or cracks on the rivet. This may be caused by poor material quality or production process issues. To improve surface quality, materials that meet quality requirements should be used, and production processes should be optimized.

- Non-compliant dimensions: Non-compliant dimensions refer to rivets whose dimensions do not meet requirements. This may be due to measurement errors or manufacturing errors during the production process. To ensure compliance with dimensions, quality control during production and calibration of measuring equipment should be strengthened.

- Material issues: Material issues refer to rivet materials that do not meet requirements, such as insufficient hardness or poor corrosion resistance. This may be due to poor quality raw materials or improper formulation ratios. To address material issues, select raw materials that meet requirements and optimize formulation ratios.

- Insufficient hardness: Insufficient hardness refers to rivet materials failing to meet hardness standards, resulting in decreased riveting performance. This may be due to improper formulation ratios or heat treatment process issues. To increase hardness, formulation ratios can be adjusted, and heat treatment processes should be optimized.

- Poor corrosion resistance: Poor corrosion resistance refers to rivets being prone to rust or corrosion when exposed to external environmental factors. This may be due to poor material quality or improper surface treatment. To improve corrosion resistance, select corrosion-resistant materials that meet requirements and perform appropriate surface treatments.

4.What are the selection considerations for SPR rivets?

- Sheet metal thickness: Choose the appropriate SPR rivet according to the thickness of the sheet metal to be riveted. Typically, the minimum overlap combination thickness is 2.5mm (corresponding to a minimum rivet length of 4.5mm), while the maximum overlap combination thickness is 9mm (corresponding to a maximum rivet length of 11mm).

- Tensile strength: The maximum tensile strength of the base plate should be less than 600MPa, depending on the tensile strength of the top plate and the total thickness. Similarly, the maximum tensile strength of the top plate should be less than 2000MPa, with a maximum thickness of 1mm, which also depends on the tensile strength of the base plate and the total thickness.

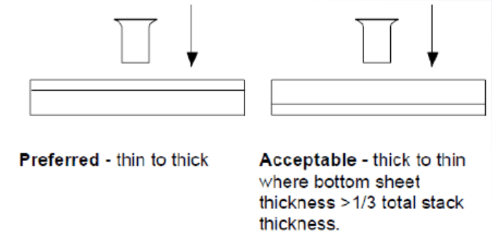

- Thickness of sheet metal on the rivet mold side: The thickness of the sheet metal on the rivet mold side should be no less than one-third of the total thickness to ensure good riveting effects.

- In addition, other factors such as material type, surface treatment, and working environment should also be considered. When selecting SPR rivets, it is recommended to consult QUESTOK engineers or manufacturers to ensure that the selected rivets are suitable for specific application scenarios and materials.

5.What are the specifications of SPR rivets?

Refer to a separate list.

6.What are the technical requirements for SPR riveting?

This aspect covers various aspects such as surface preparation, tool calibration, rivet placement, pressure application, and post-riveting inspection. These requirements ensure proper rivet installation and reliable joint integrity.

- Rivet Selection

When selecting rivets, consider the following factors:

- Sheet Metal Thickness: Choose the appropriate rivet length and diameter based on the thickness of the sheet metal to be riveted.

- Tensile Strength: The maximum tensile strength of the base plate should be less than 600MPa, and that of the top plate should be less than 2000MPa.

- Material Type: Select the appropriate rivet material and specifications according to different material types.

Working Environment: Consider the corrosion resistance, high-temperature resistance, and other performance requirements of rivets in specific working environments.

- Substrate Preparation

Before riveting, the substrate needs the following preparations:

- Cleaning: Remove oil, dirt, and other impurities from the surface of the substrate to ensure it is clean.

- Leveling: Ensure the surface of the substrate is flat with no depressions or protrusions.

- Drying: Ensure the surface of the substrate is dry with no residual moisture.

- Pre-Assembly

Before riveting, perform pre-assembly to check if the rivet can smoothly penetrate the substrate and if the rivet head fits snugly against the substrate surface.

- Positioning and Fixing

During riveting, ensure accurate positioning of the rivet to prevent offset or misalignment. Positioning fixtures or templates can be used for this purpose.

- Applying Pressure

Apply appropriate pressure during riveting to ensure the rivet is firmly pressed against the substrate surface and the sheets are tightly compressed together. Gradually increase the pressure until the rivet fully penetrates the top sheet.

- Quality Inspection

After riveting, conduct a quality inspection to ensure compliance with requirements:

- Check for loose or missing rivets.

- Inspect the substrate surface for indentations, cracks, or other defects.

- Ensure the riveted joints are firm and stable.

- Perform a pull-out test to ensure the riveted joints can withstand the specified tensile force.

- Post-processing

As needed, perform post-processing such as painting or polishing on the riveted areas to enhance aesthetics and durability. Additionally, apply rust and corrosion prevention treatments to the entire assembly to ensure its longevity.

7.The SPR riveting technology offers several advantages:

- Efficiency: This technology enables rapid completion of riveting tasks, meeting the demands of large-scale production.

- Mechanical Connection: Suitable for multi-layered board connections, capable of connecting different materials and thicknesses of sheets.

- High Joint Strength: Since the rivets directly penetrate the sheets, it achieves a robust mechanical connection with high joint strength.

- Stable Riveting Quality: The technology ensures consistent and reliable riveting results, with stable quality.

- Clean and Environmentally Friendly: As it does not require welding, it avoids the generation of smoke and exhaust fumes associated with welding, making it more environmentally friendly.

- Easy to Automate: Since the technology does not require manual operation, there are no deviations at the connection points, making it suitable for automated production lines.

- Wide Applicability: It can be used for connecting sheets of different materials, thicknesses, and shapes, with broad applicability.

- Cost-Effectiveness: Due to its high efficiency and effectiveness, it can reduce production costs.

- Strong Adjustability: By controlling the pressure applied to the rivet and the penetration depth, adjustments can be made during the riveting process to meet different requirements.

- Strong Reproducibility: Since the technology relies on mechanical connections, the joints are less prone to loosening or detachment, ensuring the reliability and stability of the connections.

These are some of the advantages of SPR riveting technology. In practical applications, it’s essential to select the appropriate riveting technology and materials based on specific requirements to achieve the best connection results.

8.The technical principle of Self-Piercing Riveting (SPR) involves four main stages:

clamping, piercing, expansion, and forming. Below is a detailed explanation of this technique using a specific example.

Taking an aluminum alloy car body as an example, each component of the aluminum alloy car body needs to be assembled through riveting after being formed by stamping. Many components of the aluminum alloy car body, such as doors, side panels, and engine covers, need to be joined together. After being formed by stamping, these components need to be assembled using the riveting process.

In the riveting process of the aluminum alloy car body, the Self-Piercing Riveting (SPR) technology is widely used. This technology inserts rivets into the panels to be joined and utilizes the special structure of the rivets along with external force to firmly connect the panels together.

Firstly, in the clamping stage, the panels to be joined are securely clamped to prevent relative movement between them.

Secondly, in the piercing stage, a specialized tool or punch is used to pierce the upper panel that has been clamped, allowing the rivet to penetrate. At the same time, excess portions of the rivet in the lower panel are cut off to facilitate the subsequent expansion and forming stages.

Next, in the expansion stage, external force is applied to expand the rivet that has passed through the upper panel in the lower panel, causing it to tightly adhere to the lower panel.

Finally, in the forming stage, after the expanded rivet tightly adheres to the lower panel, a firm mechanical connection is formed between the upper and lower panels. At this point, the upper and lower panels are securely connected to each other, forming a complete structure.

Through the application of the SPR technology principle in these four stages, various components of the aluminum alloy car body can be firmly connected to form a complete and reliable car body structure. This technology offers advantages such as high efficiency, stability, cleanliness, and environmental friendliness, making it widely used in the automotive manufacturing industry for body manufacturing and assembly.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]