The Latest Innovations in Clinching Tool Design

In the constantly developing modern manufacturing industry, the role of clinching tools is becoming more and more important. Designed to join materials with precision and efficiency, these riveting tools are at the forefront of transformative practices in the industry. The constant pursuit of innovation in clinching tool design has made major breakthroughs, reshaping the way materials are joined.

In this article, we will explore the latest innovations in clinching tool design, focusing on advancements in ergonomics, precision and efficiency, and versatility. By understanding these innovations, you can gain insight into how Questok is meeting the changing demands of the industry.

Overview of Clinching Tool

Modern manufacturing relies on a variety of tools and technologies to achieve precision, efficiency and reliability. Among these, electric clinching tools stand out as indispensable equipment, playing a vital role in joining materials safely and effectively.

What is Clinching Tool

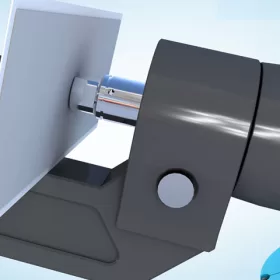

A clinching tool, also known as a clinching gun, is a mechanical device used to join sheets of material without the need for additional fasteners such as screws or welding. It usually forms a strong, permanent connection through a process called clinching.

Clinching tools are widely used in the automotive, aerospace, construction and appliance manufacturing industries, providing a faster and more cost-effective alternative to traditional joining methods. Their ability to join different materials increases their versatility and meets the ever-changing needs of modern production.

The Importance of Continuous Innovation in Clinching Tool Design

As manufacturing technology advances and industry needs change, the design of clinching tools must continue to evolve to meet new challenges and improve performance. For example, modern manufacturing often involves a variety of materials, each with unique properties. Clinching tools must continually adapt to ensure compatibility with various metals, alloys, and composite materials, expanding their range of applications.

Design innovations aim to improve the precision and control of electric riveting tools. This includes advances in material alignment, ensuring precise and consistent joints. High-precision operations help improve the overall quality and reliability of manufactured products. In addition, continuous design improvements can reduce cycle times, optimize energy consumption and streamline operations to improve overall manufacturing efficiency.

The Limitations of Traditional Clinching Tool Design

The design of traditional clinching tools has certain limitations, which stimulates the need for innovation and development. Traditional clinching methods may face challenges when dealing with a diverse range of materials. Joining dissimilar materials or those with varying thicknesses can present difficulties, limiting the tool’s versatility in modern manufacturing scenarios.

Achieving high precision and control during deformation can be challenging using traditional clinching tools. As manufacturing standards require increasingly complex designs and tighter tolerances, accuracy limitations become apparent, affecting the overall quality of the joint.

Traditional clinching tools, while effective, might fall short in speed and efficiency. In manufacturing environments where cycle times and productivity are critical, tools that can speed up the joining process without compromising quality are highly sought after. The pursuit of improved material compatibility, increased accuracy and speed has promoted the continuous development of clinching tool technology.

Ergonomic Innovations in Clinching Tool Design

In modern manufacturing industry, ergonomic design has become an indispensable part of clinching tool design. In the operation of electric clinching tools, the importance of ergonomic design is reflected in many aspects.

Good ergonomic design can significantly reduce the user’s physical burden and reduce fatigue and discomfort caused by long-term use of tools. By rationally designing the grip shape and weight distribution of the tool, the user’s physical pressure during work can be minimized, thereby improving work efficiency to a certain extent.

Ergonomic design is essential to improve the operating accuracy and stability of the handheld clinching tool for sheet metal joining. The ergonomic design can make the tool fit the human body structure more easily, making it easier for the operator to control the tool and improve the accuracy of the work. This is particularly important for clinching work that requires high-precision connections to ensure the quality of the riveting and the robustness of the connection.

Advances in Handle Design Improve Grip Strength and Comfort

A key aspect of ergonomic innovation in sheet metal clinching tool design is the evolution of handle design. The handle is the primary point of contact between the operator and the tool and is a critical component in ensuring user comfort and control. The latest innovations introduce features that significantly enhance grip strength and overall comfort during extended use.

The new handle design uses materials with enhanced tactile properties to provide a secure grip even in challenging working conditions. The handle is carefully contoured to match the natural curvature of the hand, reducing pressure and preventing discomfort. These improvements not only contribute to operator health but also have a positive impact on the precision and accuracy of the riveting process.

Integrate Adjustable Features to Suit User Preferences

The latest wave of innovation in clinching tool design has made adjustability an essential feature. Recognizing that different materials and plate thicknesses require different degrees of pressure to achieve optimal clinching quality, modern handheld clinching tools are equipped with adjustable features. Operators have the flexibility to fine-tune tool settings based on specific application requirements.

A notable example is the use of the 350° free rotating arm, which provides unparalleled maneuverability in different working environments. This dynamic range of motion ensures operators can access tight spaces and optimize tool positioning for different applications. In addition, a variety of arm adjustment options are available to meet the needs of different users, providing a customizable experience that suits personal preferences.

Design Improvements in Accuracy and Efficiency

Clinching tools, essential in modern manufacturing, have significant design improvements, particularly in enhancing accuracy and efficiency. These advances not only meet the need for high-precision operations but also help streamline processes to improve efficiency.

Advances in Alignment and Accuracy

One notable area of improvement lies in the area of alignment and accuracy for high-precision operations. Precision is paramount in manufacturing, especially in applications where riveting tools are used. Design innovations focus on improving the alignment mechanisms within these tools, ensuring impeccable accuracy during operation.

Clinching tools equipped with precise alignment systems can achieve unparalleled accuracy, aligning components with utmost precision. Whether in automotive manufacturing, aerospace, or other industries, these riveting tools help produce complex structures where precision cannot be compromised.

Increase Efficiency Through Faster Operation and Shorter Cycle Time

Efficiency is the cornerstone of modern manufacturing, and design improvements in clinching tools are aimed at increasing operating speeds and reducing cycle times. Faster operations not only speed up the manufacturing process but also help improve overall productivity.

The integration of advanced motor systems and optimized mechanical components enables clinching tools to operate at higher speeds without compromising accuracy. The reduction in cycle time is particularly beneficial in high-volume production scenarios, where the time saved in each cycle accumulates to significantly improve the overall production output.

The Versatility of Clinching Tool Applications

In the ever-evolving modern manufacturing landscape, clinching tools have undergone transformative innovations to enhance their versatility. This adaptability is critical to meeting the diverse needs of various industries.

Expanding the Range of Compatible Materials

A major advance in the versatility of clinching tools is their ability to accommodate a wider range of materials. Traditionally limited to specific alloys, clinching guns are now engineered to work seamlessly with high-strength alloys, giving manufacturers greater flexibility in material selection without compromising the integrity of the joint.

This expanded compatibility is particularly noteworthy in aerospace applications, where lightweight materials play a key role. Riveting tools have adapted to handle these aerospace-grade materials efficiently, helping to build lighter yet stronger aircraft and spacecraft structures.

Adjustable Settings for Different Material Thicknesses

Another aspect of versatility is the ability to handle different material thicknesses. Clinching tools now feature adjustable settings, providing solutions to the challenges posed by different material thicknesses. This adaptability ensures that the tool can effectively penetrate and secure joints of various material thicknesses, thereby promoting uniformity in the quality of clinched joints.

The Role of Multifunctional Clinching Tools Across Industries

Multifunctional sheet metal clinching tools have become an indispensable asset and are used in different industries. Their adaptability to different materials, thicknesses, and joining requirements makes them a versatile solution in manufacturing scenarios where different needs exist.

The automotive, aerospace, and construction industries, among others, benefit from the multifaceted capabilities of these tools. They streamline processes, reduce the need for multiple specialized tools, and help improve overall cost-effectiveness. Versatile clinching tools do more than just create strong joints, they play a key role in shaping efficient, versatile manufacturing practices across industries.

Conclusion

In the dynamic world of manufacturing, clinching tools have undergone significant transformation, redefining the landscape of material joining. The latest advances in clinching gun design illustrate significant advances in improving efficiency, versatility, and precision.

A review of the latest innovations reveals the multifaceted evolution of clinching tool design. Ergonomic considerations have redefined the user experience, with handles designed to prioritize grip and comfort, coupled with adjustable features to meet individual user preferences. The expansion of compatible materials is a key breakthrough that gives manufacturers the freedom to explore high-strength alloys and lightweight materials for aerospace applications.

The high precision operation and higher efficiency provided by modern clinching tools directly contribute to the advancement of the manufacturing industry. Faster operations and shorter cycle times mean faster turnaround, allowing manufacturers to meet market demand more flexibly and sustainably.

Questok’s clinching tools are a range of innovative manufacturing tools that combine advanced technology with superior design. Engineered to the highest standards of efficiency and versatility, our clinching tools are reshaping the landscape of material joining in manufacturing.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]