Unveiling the Technology Behind Self-Piercing Riveting Guns

Self-piercing Riveting In Auto Market

In modern manufacturing, joining technology plays a key role in creating reliable, durable connections between various materials. One of the technologies that has attracted much attention, especially in the automotive industry, is self-piercing riveting (SPR). This innovative joining technology has numerous advantages that make it an important tool for engineers and manufacturers working to improve structural integrity, reduce weight and increase the overall efficiency of vehicle production. Self-piercing riveting (SPR) is used extensively in many modern manufacturing applications. It uses pressure and heat to drive the rivet directly into the metal surface, creating a strong bond between the materials. This process eliminates the use of fasteners, greatly reducing space requirements during production. In the automotive industry, SPR technology has proven to be an excellent solution, as it offers car manufacturers a way to join dissimilar metal parts without welding or fasteners.

However, the advantages of SPR technology do not stop there. This connection technology can also reduce the weight of the car, thereby improving fuel efficiency. This is undoubtedly a huge attraction for automakers who are increasingly emphasizing environmental protection. Additionally, SPR technology enables precise joins in complex geometries and small areas, which are critical for many critical applications in modern automotive manufacturing. In the future, self-piercing riveting (SPR) technology will continue to play an important role in modern manufacturing as joining technologies continue to develop and improve. For example, researchers are working on developing new types of SPR devices that can operate at high temperatures, high pressures and high speeds, enabling faster and more precise joining processes.

In addition, by using advanced data analysis and artificial intelligence algorithms, we can predict and optimize the joining process to meet the needs of different applications. In modern manufacturing, automation and digitalization are key factors driving productivity improvements. By introducing self-piercing riveting (SPR) technology, automakers can use automated equipment and robots to achieve precise production processes, thereby increasing production efficiency and reducing production costs. This automated production method can also reduce human error and improve product quality.

In addition, the sustainability of self-piercing riveting (SPR) technology is an important reason for its interest in modern manufacturing. This connection technology can effectively reduce energy consumption, reduce waste generation, and thus reduce the impact on the environment. Therefore, more and more automakers are paying attention to this environmentally friendly connection technology, hoping to achieve sustainable development goals by adopting this technology. In the future, self-piercing riveting (SPR) technology will continue to be improved and optimized as new materials and technologies continue to emerge. For example, the use of nanotechnology and new materials can improve joint strength and fatigue resistance, allowing automakers to achieve greater safety and longer service life.

The advantages of self-piercing riveting (SPR) technology give it great potential in modern manufacturing. As joining technology continues to evolve and innovate, there is reason to believe that self-piercing riveting (SPR) technology will continue to play a key role in modern manufacturing, bringing more efficient and reliable solutions to automakers. With the advancement of science and technology, the production process of various industries around the world is undergoing earth-shaking changes. In response to changing market demands, automakers are actively looking for more efficient and environmentally friendly production methods. In this context, self-piercing riveting (SPR) technology, as an innovative joining technology, undoubtedly provides a new choice for car manufacturers.

How To Choose A Good Self-piercing Riveting Gun ?

Choosing a good self-piercing riveting gun is essential to ensure efficient and reliable riveting processes. Here are some factors to consider when selecting a self-piercing riveting gun:

Rivet Size and Material Compatibility: Different riveting guns are designed to accommodate specific rivet sizes and types. Ensure that the gun you choose can handle the rivet sizes and materials you intend to work with. Consider the range of rivet diameters and materials supported by the gun.

Application and Use Case: Consider the intended application for the riveting gun. Are you using it for lightweight automotive panels, heavy-duty structural components, or something else? The gun’s design and capabilities should align with your specific use case.

Force and Power: The force generated by the riveting gun is crucial for driving rivets through various materials. Ensure that the gun has sufficient force to penetrate the materials you’ll be working with. Higher force is often required for thicker and tougher materials.

Adjustability and Control: Look for a riveting gun that offers adjustable settings for force, depth, and speed. This adaptability allows you to optimize the riveting process for different materials and joint requirements.

Ergonomics and Comfort: Since riveting can be a repetitive task, an ergonomically designed gun will reduce operator fatigue and improve overall efficiency. Comfortable grips, balanced weight distribution, and minimal vibration contribute to a better user experience.

Durability and Build Quality: Choose a riveting gun made from durable materials that can withstand the demands of industrial use. A sturdy construction ensures a longer lifespan and consistent performance over time.

Maintenance and Servicing: Consider the ease of maintenance and availability of spare parts. A riveting gun that is easy to disassemble, clean, and repair can save time and reduce downtime.

Safety Features: Safety is paramount when using any industrial tool. Look for features such as safety interlocks, guards, and ergonomic designs that minimize the risk of accidents during operation.

Compatibility with Automation: If you plan to integrate the riveting process into an automated production line, ensure that the riveting gun can be easily integrated with robotic systems and automation equipment.

Brand Reputation and Support: Choose a reputable brand known for producing high-quality industrial tools. A reliable manufacturer often provides better customer support, warranties, and assistance with technical issues.

Reviews and Recommendations: Research online reviews and seek recommendations from colleagues or industry professionals who have experience with self-piercing riveting guns. Their insights can provide valuable information about the practical performance and reliability of different models.

Deep Dive into the Self-Piercing Riveting Gun Process

In the world of modern manufacturing, where innovation reigns supreme, traditional joining methods often give way to more advanced techniques. Among these, self-piercing riveting has emerged as a crucial player, particularly in industries like automotive manufacturing, where lightweight yet sturdy connections are paramount. In this exploration, we take a comprehensive journey into the self-piercing riveting gun process, uncovering its mechanics, applications, benefits, and how it’s shaping the future of manufacturing.

Understanding Self-Piercing Riveting: Breaking Down the Basics

At its core, self-piercing riveting is a method of joining two or more layers of material without the need for pre-drilled holes, as in traditional riveting. The process involves driving a rivet through the materials, creating a strong and durable connection. Unlike welding, which can pose challenges with certain materials, self-piercing riveting thrives in joining dissimilar materials, such as aluminum and high-strength steels, that are integral to lightweight vehicle construction.

The Mechanics Behind the Self-Piercing Riveting Gun

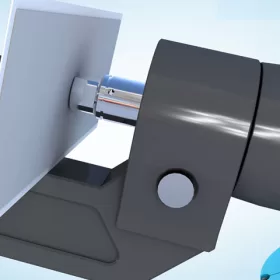

At the heart of this process lies the self-piercing riveting gun, a tool designed for precision, power, and efficiency. The gun consists of several key components that work in harmony to achieve a successful riveting operation:

Rivet Placement: The riveting gun accurately positions the rivet on the materials to be joined. This positioning ensures optimal rivet penetration and joint integrity.

Force Application: The gun generates controlled force to drive the rivet through the layers of material. This force is crucial for achieving a strong and secure joint.

Die Set: The die set supports the materials being riveted and provides the counterforce required to form the rivet properly. It plays a pivotal role in shaping the rivet and creating a reliable connection.

Adjustability: Many modern self-piercing riveting guns offer adjustable settings for force, depth, and speed. This adaptability allows operators to tailor the riveting process to different materials and specific joint requirements.

Applications Across Industries: Where Self-Piercing Riveting Shines, While the automotive industry has embraced self-piercing riveting for its ability to join lightweight materials and enhance structural integrity, its applications extend to various sectors:

Aerospace: In aerospace manufacturing, self-piercing riveting is used for assembling components where the absence of holes helps maintain aerodynamic efficiency.

Construction: Self-piercing riveting aids in constructing steel frames and joining architectural panels, where speed and structural soundness are crucial.

Consumer Electronics: The technique is employed to assemble electronics enclosures and components that require sturdy connections without compromising aesthetics.

Advantages Galore: The Benefits of Self-Piercing Riveting

The adoption of self-piercing riveting guns brings forth a plethora of advantages that impact both the manufacturing process and the end product:

Material Versatility: The ability to join dissimilar materials opens the door to creative engineering solutions and innovative design possibilities.

Weight Reduction: Particularly in the automotive industry, self-piercing riveting contributes to weight reduction by facilitating the use of lightweight materials, leading to improved fuel efficiency.

Structural Integrity: The robust joints created by self-piercing riveting enhance the structural integrity of components, making them better suited to handle various stresses and strains.

Reduced Heat-Affected Zone: Unlike welding, self-piercing riveting minimizes the heat-affected zone, preserving material properties and reducing the risk of distortion.

Clean Aesthetics: The absence of visible weld seams lends a clean and aesthetically pleasing finish to products, contributing to their overall appeal.

Looking Ahead: Self-Piercing Riveting Guns in the Future of Manufacturing

As technology continues to evolve, self-piercing riveting guns are poised to play an even more significant role in the manufacturing landscape. The integration of automation, robotics, and advanced process monitoring is set to enhance efficiency, accuracy, and consistency in riveting operations. Furthermore, ongoing research into new materials, sustainable practices, and optimized processes promises to expand the capabilities of self-piercing riveting, making it a cornerstone of modern manufacturing practices.

In conclusion, QUESTOK self-piercing riveting gun process is a testament to the strides made in joining technology. Its ability to create strong, reliable, and visually appealing connections across various industries underscores its importance in the world of manufacturing. With advancements on the horizon, the journey of self-piercing riveting is one of continuous innovation, pushing the boundaries of what is possible in the realm of joining techniques.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]