The Future of Electric Car Body Repair- Predictions and Trends

Introduction:

In the realm of automotive evolution, electric vehicles (EVs) are charging ahead, leaving conventional cars in their dust. As the adoption of EVs accelerates, the landscape of car body repair is poised for a transformative shift. Here, we explore the groundbreaking predictions and trends that are shaping the future of EV body repair.

Lightweight Materials and Advanced Construction:

EVs embrace lightweight materials such as carbon fiber, aluminum, and high-strength steel. These materials enhance vehicle performance and efficiency, but they require specialized repair techniques. Repair shops will need to invest in advanced equipment and training to handle these composite structures.

High-Voltage Systems Safety:

EVs operate on high-voltage electrical systems. This poses unique safety concerns for repair technicians. New protocols and training programs will be implemented to ensure the safe handling and repair of high-voltage components.

Battery Damage and Replacement:

EV batteries are complex and expensive components. Their size and weight present challenges for transportation and storage. As battery technology evolves, the repair process will become increasingly sophisticated, requiring specialized knowledge and equipment.

Autonomous Driving Technology:

The advent of autonomous driving technology will impact the frequency and nature of car accidents. Potential repairs could shift from collision damage to sensor and software issues, demanding new skill sets for technicians.

Usage of AI and Data Analytics:

Artificial intelligence (AI) and data analytics will play a pivotal role in EV body repair. Advanced diagnostic tools will aid in the identification and assessment of damage, optimizing repair efficiency and accuracy.

Sustainability and Environmental Regulations:

The push for sustainability will extend to EV body repair. Eco-friendly materials and processes will be prioritized to minimize waste and environmental impact. Government regulations will also influence the adoption of innovative repair techniques.

Conclusion:

The future of electric car body repair is electrifying, with advancements shaping the industry at every turn. As lightweight materials, high-voltage systems, and autonomous driving technology become more prevalent, the demand for specialized knowledge and skill will soar. By embracing these trends, repair shops can position themselves as experts in the emerging realm of EV body repair, ensuring the safety and longevity of these innovative vehicles.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

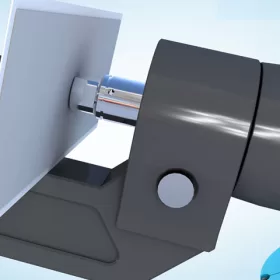

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]