Safety Considerations When Working with Industrial Solid Rivets

In the realm of industrial fabrication, the unyielding force of solid rivets binds materials with unwavering strength. Yet, their formidable power demands utmost vigilance and adherence to safety protocols. Let’s delve into the critical considerations that ensure safety when working with these formidable tools.

Eye Protection Paramount

Riveting operations unleash a barrage of flying debris and sparks. Donning safety glasses or goggles is paramount to shield your eyes from potential projectiles. These safeguards prevent corneal abrasions, lacerations, or even catastrophic vision loss. Ensure the lenses are impact-resistant and remain secure throughout the riveting process.

Hand Protection Essential

The forceful driving of rivets against material can wreak havoc on unprotected hands. Heavy-duty work gloves provide a vital barrier against pinching, lacerations, and abrasions. Choose leather or nitrile gloves with reinforced palms to withstand the rigors of riveting and prevent hand injuries.

Respiratory Protection

The rivets’ relentless pounding can generate hazardous dust particles. Inhaling these fine particles poses significant respiratory risks, including irritation, asthma, or even lung damage. Wear an approved dust mask or respirator to filter harmful contaminants from inhaled air. Remember, particle concentrations rise in enclosed or poorly ventilated areas, necessitating heightened respiratory protection.

Fire Prevention

Friction and heat buildup during riveting create a significant fire hazard. Wear fire-resistant clothing, keep a fire extinguisher nearby, and avoid working in areas with flammable materials. Extinguish open flames and sparks promptly to prevent accidental fires.

Workstation Setup

A well-organized workstation mitigates safety risks. Ensure the riveting area is free of clutter and obstacles, allowing for clear movement. Use appropriate clamps and vises to secure workpieces and prevent slipping or shifting. Proper workpiece positioning eliminates potential rivet head projections and reduces the risk of accidental contact with rotating or reciprocating tools.

Training and Supervision

Proper training is non-negotiable when working with industrial solid rivets. Familiarize yourself with the equipment, techniques, and safety protocols. Seek guidance from experienced personnel or certified trainers. Supervision by a qualified professional ensures adherence to safety standards and promotes a positive safety culture.

Emergency Preparedness

Despite all precautions, accidents can occur. Keep a first-aid kit readily accessible and know the location of the nearest medical facility. Train yourself in basic first aid to respond effectively to minor injuries. Reporting all incidents, even seemingly minor ones, is crucial for continuous safety improvement and risk mitigation.

In the realm of industrial fabrication, solid rivets reign supreme with their unrivaled holding power. However, their use demands a profound respect for safety. By adhering to these critical considerations, you safeguard yourself and others against potential hazards, ensuring a productive and injury-free work environment. Remember, safety is not just a priority; it’s an unwavering commitment that empowers us to harness the transformative power of industry with confidence and peace of mind.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

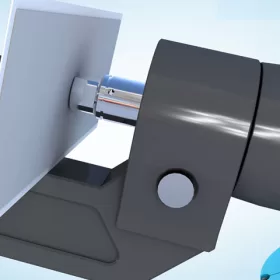

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]