How to Choose the Right Size and Type of Aluminum Solid Rivets

Aluminum solid rivets are a versatile and commonly used type of fastener in various industrial applications. They offer excellent strength, corrosion resistance, and ease of installation. Choosing the right size and type of aluminum solid rivets is crucial to ensure proper performance and safety.

Material and Strength

Aluminum solid rivets are available in various alloys, each offering specific strength characteristics. The most commonly used alloys include 2017-T4 (standard strength), 2117-T4 (high strength), and 7050-T6 (aerospace grade). The strength requirement of the application will determine the appropriate alloy.

Diameter and Length

The diameter of the rivet refers to the thickness of the material it is designed to join. The length of the rivet is measured from the top of the head to the end of the shank. Both the diameter and length should be carefully selected to ensure sufficient strength and avoid overstressing or splitting the material.

Head Style and Grip Range

The head style of a rivet refers to the shape of its head. Common head styles include flat, countersunk, and button. The grip range specifies the thickness of the material that the rivet can accommodate. The head style and grip range should be chosen based on the application and the space available.

Drive Type

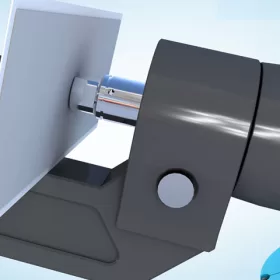

Aluminum solid rivets can be installed using various drive types, including hand rivets, rivet guns, and robotic riveters. The drive type should be compatible with the rivet design and the available equipment.

Corrosion Resistance

Aluminum is naturally corrosion-resistant, making it suitable for use in harsh environments. However, some applications may require additional corrosion protection. Anodized rivets provide increased corrosion resistance and can be used in marine or chemical environments.

Considerations for Specific Applications

Choosing the right type of rivet also depends on specific applications:

Aerospace: High-strength 7050-T6 rivets are commonly used in aerospace applications where weight and strength are critical.

Automotive: Standard strength 2017-T4 rivets are suitable for automotive applications, such as body panels and chassis components.

Construction: High-strength 2117-T4 rivets are often used in construction projects where load-bearing connections are required.

Conclusion

Choosing the right size and type of aluminum solid rivets is essential for ensuring the proper performance and safety of the application. By considering the material, strength, diameter, length, head style, grip range, drive type, corrosion resistance, and specific application requirements, engineers and technicians can select the most appropriate rivets for their projects.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]