Customization Made Easy- Tailoring Cordless Electric Rivet Guns to Your Needs

In the realm of industrial and construction tasks, cordless electric rivet guns have emerged as indispensable tools. Offering portability and efficiency, these devices have revolutionized the way we fasten materials together. However, not all rivet guns are created equal, and the ability to customize them to meet specific needs is crucial for optimal performance.

Versatility for Diverse Applications

Cordless electric rivet guns cater to a wide array of applications, from automotive repair to sheet metal fabrication. Customization allows you to tailor the gun to the materials you’re working with. Different nosepieces accommodate various rivet sizes and shapes, enabling you to tackle a range of tasks with ease. Whether you’re dealing with aluminum, steel, or stainless steel, there’s a rivet gun configuration that suits your needs.

Ergonomic Comfort for Extended Use

Comfort is essential when working with power tools for extended periods. Customization options allow you to tailor the grip, handle, and weight of your rivet gun for maximum comfort. Non-slip handles provide a secure hold, while adjustable trigger sensitivity reduces fatigue. Additionally, lightweight models minimize strain on your hands and arms, ensuring extended use without discomfort.

Productivity Boost with Accessories

To enhance productivity, consider accessorizing your cordless electric rivet gun. Vacuum adapters conveniently collect rivet stems, preventing them from scattering around the work area. LED lights illuminate dimly lit spaces, ensuring precision during operation. Extension noses reach into tight spots, enabling you to fasten rivets in otherwise inaccessible areas. By outfitting your gun with the right accessories, you can streamline your workflow and maximize efficiency.

Safety Features for Peace of Mind

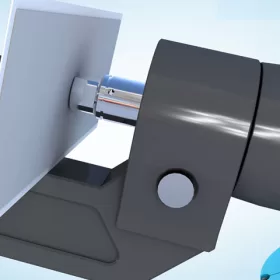

Safety is paramount when using power tools. Customization options include safety features that safeguard your well-being. Non-slip barrels prevent the gun from jarring loose, while anti-jam mechanisms minimize the risk of rivet breakage. Ergonomic designs reduce fatigue, helping you maintain focus and control during operation. By prioritizing safety, you can work confidently and reduce the potential for accidents.

Durability for Heavy-Duty Applications

For heavy-duty tasks or industrial environments, durability is a key consideration. Customization options provide reinforced components and robust construction materials to withstand the demands of extended use. Armor-plated housing protects the gun from drops and impacts, while hardened jaws and shafts ensure longevity and reliability. Investing in a durable rivet gun ensures it can endure the rigors of your projects.

Conclusion

Customization is an invaluable feature when choosing a cordless electric rivet gun. By tailoring the tool to your specific needs, you can unlock maximum versatility, comfort, productivity, safety, and durability. Whether you’re a professional contractor or a DIY enthusiast, customizing your rivet gun empowers you to optimize your tasks and achieve impeccable results. Embrace the customization options available and elevate your rivet gun to the next level of performance and efficiency.

- Company News

- Industry News

- Tag

- Tags

-

The Advantages of Questok Rivet Guns: Precision, Efficiency, and Durability

In industrial fastening applications, the choice of tools directly impacts productivity, safety, and long-term cost-effectiveness. Questok rivet guns have emerged as a standout solution for professionals across aerospace, automotive, and construction sectors. Combining advanced engineering with user-centric design, these tools deliver unmatched performance. Below are the key advantages that make Questok rivet guns a preferred choice:

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Fast Assembly and Repair With Cordless Solid Rivet Gun

Questok cordless solid rivet gun stands out as a pivotal innovation, merging portability with power to facilitate efficient and effective fastening in a myriad of applications.

-

Redifine The Role of Self-piercing Riveting Gun Machine

Self-piercing riveting adopts high-speed mechanical fastening skill that joins thin sheet materials, typically steel and aluminum alloys.

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]