Understanding Material Compatibility and Rivet Selection with Electric Solid Rivet Guns

Electric solid rivet guns are indispensable tools for joining materials in various industries, including automotive, electronics, and construction. However, to ensure optimal performance and longevity, it is crucial to understand the compatibility between the materials being joined and the rivets used. This article provides a comprehensive guide to material compatibility and rivet selection for electric solid rivet guns, empowering users to make informed decisions and achieve precise, durable joints.

Material Compatibility

The materials being joined determine the type of rivets and fasteners to be used. Electric solid rivet guns are compatible with a wide range of materials, including:

– Metals: Aluminum, steel, stainless steel, copper, and brass are commonly used metals for riveting.

– Plastics: Thermoplastics, thermosets, and composites are compatible with electric solid rivet guns when proper rivets are chosen.

– Wood: Electric solid rivet guns can join wood when using the right rivets, considering wood’s inherent properties.

Rivet Types

Electric solid rivet guns use various types of rivets, each with its own advantages and compatibility with different materials:

– Aluminum rivets: Soft and versatile, ideal for joining aluminum sheets and other non-ferrous metals.

– Steel rivets: Strong and durable, suitable for high-stress applications where strength is paramount.

– Stainless steel rivets: Corrosion-resistant, commonly used in harsh environments or where aesthetics are critical.

– Copper rivets: Excellent electrical conductivity, perfect for electrical applications.

– Plastic rivets: Lightweight and non-conductive, ideal for joining plastic components.

Rivet Selection Considerations

Choosing the appropriate rivet for electric solid rivet guns involves considering several key factors:

– Material thickness: Select rivets with the right length and diameter to successfully penetrate and join the materials.

– Joint strength: Determine the required strength of the joint to choose rivets with the appropriate strength rating.

– Environment: Consider operational conditions such as temperature, moisture, and chemicals to select rivets with suitable corrosion resistance.

– Head style: Opt for domed, flat, or countersunk rivet heads depending on the aesthetic and functional requirements.

– Set time: Choose rivets with the optimal set time for the desired application, ensuring proper joint formation.

Best Practices for Riveting

For optimal results with electric solid rivet guns, follow these best practices:

– Clean the surfaces: Prepare the materials by removing any dirt or debris before riveting.

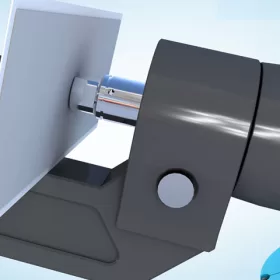

– Use the correct nosepiece: Select the appropriate nosepiece for the rivet type and size to ensure proper rivet insertion.

– Maintain alignment: Align the rivet gun perpendicular to the joint to prevent uneven riveting.

– Apply appropriate force: Apply the necessary force when squeezing the trigger to achieve a solid and complete set.

– Inspect the joint: Visually inspect the riveted joint to ensure proper formation and adequate strength.

Conclusion

Understanding material compatibility and rivet selection is essential for effective use of electric solid rivet guns. By considering the materials, rivet types, and application requirements, users can make informed decisions and achieve secure, reliable, and aesthetically pleasing joints. By adhering to best practices, users can maximize the performance and longevity of their electric solid rivet guns while ensuring the integrity and durability of their projects.

- Company News

- Industry News

- Tag

- Tags

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Future of Joining- Electric Clinching Guns Leading the Way

In the realm of manufacturing, where innovation thrives, a new era is dawning. Electric clinching guns are emerging as the frontrunners in the evolution of joining technologies, revolutionizing the way we assemble materials. Electric clinching guns harness advanced electromagnetism to achieve superior joint strength and unmatched precision. Unlike traditional mechanical methods, they employ non-contact joining, […]

-

Eco-Friendly Riveting- Sustainability with Cordless Electric Rivet Guns

Introduction In the realm of construction and manufacturing, sustainability has become an imperative concern. From sourcing materials to managing waste, industries are seeking innovative ways to reduce their environmental impact. One such area is riveting, a fundamental process that joins metal components together. Enter cordless electric rivet guns – a game-changer for eco-conscious operations. Eliminating […]

-

Precision Control- Fine-Tuning Fastening Operations with Self-Clinching Nut Tools

In the realm of manufacturing, precision is paramount. From the delicate assembly of microelectronics to the heavy-duty construction of bridges, precise fastening operations are crucial for ensuring structural integrity and performance. Enter self-clinching nut tools, the unsung heroes of precision fastening. These ingenious tools revolutionize the way permanent threaded inserts are installed. Unlike traditional nut […]

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

The Clinching Revolution- How This Joining Technique is Transforming Metalwork

The Clinching Revolution: A Paradigm Shift in Metalworking The Clinching Revolution: How This Joining Technique is Transforming Metalwork is a groundbreaking work that delves into the transformative power of clinching as a metalworking technique. Clinching, a mechanical joining method that involves cold forming interlocking joints, is revolutionizing the field, offering a versatile and cost-effective alternative […]

-

The Future of Metal Fastening- Exploring Advancements in Hand-Held Rivet Gun Technology

In the ever-evolving realm of metalworking, the humble rivet gun stands poised to undergo a seismic shift. Advancements in hand-held rivet gun technology are ushering in an era of unparalleled precision, efficiency, and versatility. From aerospace giants to construction contractors, industries worldwide rely on the secure and durable bond provided by rivets. Traditional rivet guns, […]

-

Strong & Secure- The Benefits of Using Hand-Held Rivet Guns for Any Project

In the realm of DIY and professional construction, securing components with unwavering strength and precision is paramount. Enter hand-held rivet guns”unsung heroes that transform ordinary projects into masterpieces of durability. Let’s delve into the unparalleled advantages they offer: Unleash the Strong Hold: Rivets, when coupled with the relentless force of rivet guns, establish an unyielding […]

-

The Future of Metal Joining- Advancements in Sheet Metal Clinching Technology

In an era marked by technological breakthroughs, the realm of metal joining has witnessed a transformative innovation: sheet metal clinching. This groundbreaking technique is redefining the way we assemble sheet metal components, pushing the boundaries of efficiency and reliability. Sheet metal clinching, a cold-forming process that mechanically interlocks metal sheets without the use of adhesives […]