The Ultimate Guide to Electric Rivet Guns- Everything You Need to Know

The Ultimate Guide to Electric Rivet Guns: An In-Depth Exploration

For those unfamiliar with the concept, electric rivet guns are indispensable tools for fastening materials together through the use of rivets. They offer a superior alternative to manual riveters, providing greater ease, speed, and consistency in the riveting process. The Ultimate Guide to Electric Rivet Guns: Everything You Need to Know serves as a comprehensive resource for anyone seeking to understand and effectively use these remarkable tools.

Types of Electric Rivet Guns

Electric rivet guns come in two main types: corded and cordless. Corded models provide continuous power from an electrical outlet, allowing for prolonged use without interruptions. Cordless models, on the other hand, offer the convenience of portability and freedom from the constraints of cords. They utilize rechargeable batteries that provide a finite amount of operating time before requiring recharging.

Choosing the Right Electric Rivet Gun

Selecting the appropriate electric rivet gun for a specific application involves considering several factors. The type of material being riveted, the size and diameter of the rivets, and the intended usage frequency all play a role. For heavy-duty industrial tasks, corded models with high power ratings are often preferred. For smaller projects and general usage, cordless models provide a portable and convenient option.

Safety Considerations

As with any power tool, safety is paramount when using electric rivet guns. Always wear appropriate safety gear, including safety glasses, gloves, and earplugs. Ensure that the work area is well-lit and free from potential hazards. Properly maintain the rivet gun by regularly lubricating moving parts and checking for any signs of damage or wear.

Operation and Maintenance

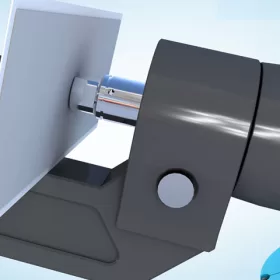

Operating an electric rivet gun is relatively straightforward. Insert the appropriate rivet into the gun’s nosepiece, align the gun with the desired fastening point, and squeeze the trigger. The gun’s motor will drive the rivet shank into the material, creating a permanent and secure joint. Proper maintenance, such as regular cleaning and lubrication, is crucial for ensuring optimal performance and longevity of the tool.

Alternatives to Electric Rivet Guns

While electric rivet guns offer numerous advantages, they may not be suitable for all riveting applications. For situations where portability and ease of use are critical, manual riveters or pneumatic rivet guns can serve as viable alternatives. Manual riveters require manual force to set rivets, while pneumatic rivet guns utilize compressed air for power.

Conclusion

The Ultimate Guide to Electric Rivet Guns: Everything You Need to Know is an invaluable resource for anyone interested in acquiring a comprehensive understanding of these versatile tools. By providing detailed information on different types of electric rivet guns, selection criteria, safety considerations, operation and maintenance, and alternative riveting methods, this guide empowers readers to make informed decisions and utilize electric rivet guns effectively for their specific riveting needs.

- Company News

- Industry News

- Tag

- Tags

-

What to Look For in a High-Quality Cordless Electric Rivet Gun

In the realm of riveting, where precision meets power, cordless electric rivet guns reign supreme. These indispensable tools empower professionals and DIY enthusiasts alike with the ability to join materials with unmatched efficiency. However, navigating the vast array of options available can be a daunting task. To guide you on this riveting journey, we delve […]

-

How to Select the Best Flat Head Solid Rivet for Your Application

In the realm of fastening solutions, flat head solid rivets stand out as a robust and versatile choice. Understanding how to select the optimal rivet for your specific application is crucial to ensure a reliable and long-lasting joint. This article provides a comprehensive guide to navigating the considerations involved in choosing the best flat head […]

-

Innovative Uses for the Ford Aluminum Rivet Gun in DIY Projects

The Ford Aluminum Rivet Gun is a versatile tool that can be used for a variety of home improvement projects. While it is most commonly used for riveting aluminum, it can also be used to work with other materials such as steel, plastic, and fiberglass. In this article, we will explore some of the innovative […]

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]