Step-by-Step Guide to Installing Stainless Steel Hollow Rivets

In the realm of metalworking, where precision and durability collide, the humble stainless steel hollow rivet emerges as an essential component. Whether you’re a seasoned craftsman or a novice embarking on a riveting adventure, this guide will illuminate the path to flawless installation.

Materials You’ll Need:

Stainless steel hollow rivets

Drill or punch

Anvil or backing block

Riveting tool (hammer or rivet gun)

Step 1: Prepare the Materials

Measure and mark the location where the rivet will be installed. Select a rivet of appropriate diameter and length for the application.

Step 2: Drill or Punch the Hole

Using a drill or punch, create a hole through the materials to be joined. The hole diameter should match the rivet shank.

Step 3: Position the Rivet

Insert the rivet through the hole from the top side. Place an anvil or backing block underneath the rivet head.

Step 4: Set the Rivet

Use a riveting tool to set the rivet. If using a hammer, strike the rivet head firmly and evenly. If using a rivet gun, follow the manufacturer’s instructions.

Step 5: Form the Bucktail

As the rivet is set, the shank will form a bucktail on the bottom side. Using the rivet tool, flatten and spread the bucktail to secure the rivet.

Step 6: Inspect the Rivet

Once the rivet is installed, inspect it for proper formation and tightness. The head should be flush with the surface, and the bucktail should be evenly spread.

Tips for Success:

Use a sharp drill bit to prevent burring and misalignment.

Ensure that the anvil or backing block is securely positioned.

Apply moderate force to set the rivet without damaging the materials.

Allow the rivet to cool before handling to prevent deformation.

By following these steps meticulously, you can install stainless steel hollow rivets with confidence and precision. These durable fasteners will provide reliable connections in a wide range of applications, from industrial machinery to decorative projects.

- Company News

- Industry News

- Tag

- Tags

-

What to Look For in a High-Quality Cordless Electric Rivet Gun

In the realm of riveting, where precision meets power, cordless electric rivet guns reign supreme. These indispensable tools empower professionals and DIY enthusiasts alike with the ability to join materials with unmatched efficiency. However, navigating the vast array of options available can be a daunting task. To guide you on this riveting journey, we delve […]

-

How to Select the Best Flat Head Solid Rivet for Your Application

In the realm of fastening solutions, flat head solid rivets stand out as a robust and versatile choice. Understanding how to select the optimal rivet for your specific application is crucial to ensure a reliable and long-lasting joint. This article provides a comprehensive guide to navigating the considerations involved in choosing the best flat head […]

-

Innovative Uses for the Ford Aluminum Rivet Gun in DIY Projects

The Ford Aluminum Rivet Gun is a versatile tool that can be used for a variety of home improvement projects. While it is most commonly used for riveting aluminum, it can also be used to work with other materials such as steel, plastic, and fiberglass. In this article, we will explore some of the innovative […]

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

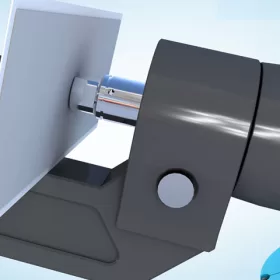

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]

-

Top Features and Benefits of Universal Self-Piercing Riveting Guns

In the realm of metalworking, precision and efficiency are paramount. Universal self-piercing riveting guns, often referred to as self-pierce riveting guns, embody these qualities, offering remarkable benefits for various applications. These innovative tools feature technologically advanced functions that enhance productivity, reliability, and overall performance, making them indispensable in industries such as aerospace, automotive, construction, and […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]