Quality Control- Ensuring Reliable Results with Cordless Electric Rivet Guns

In the realm of construction and manufacturing, achieving reliable and consistent results is paramount. Cordless electric rivet guns have revolutionized these industries, offering unparalleled convenience and efficiency. However, ensuring the quality and accuracy of these tools is crucial for optimal performance. This article explores the comprehensive quality control measures employed to guarantee the reliability of cordless electric rivet guns, ensuring dependable outcomes in all applications.

Material Selection and Inspection

The foundation of quality control lies in the selection and inspection of high-grade materials. Rigorous tests are conducted to evaluate the durability, strength, and corrosion resistance of each component. The use of aircraft-grade aluminum alloys and hardened steel for critical parts ensures the tool’s longevity and ability to withstand demanding conditions. Precise dimensions and tolerances are meticulously verified to ensure perfect fit and functionality.

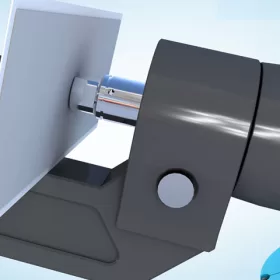

Assembly and Calibration

The assembly process is meticulously controlled to maintain the highest standards of precision and accuracy. Each component is cuidadosamente inspected and calibrated to ensure flawless operation. Automated assembly lines are employed to minimize human error and guarantee consistent quality. Every rivet gun undergoes rigorous functional testing to verify its performance before shipment.

Performance Testing

Comprehensive performance testing is an essential aspect of quality control. Rivet guns are subjected to a battery of tests to evaluate their pulling force, breaking torque, and vibration levels. These tests gauge the tool’s ability to deliver consistent and reliable performance under varied conditions. Advanced testing equipment, such as strain gauges and load cells, ensures accurate and precise measurements.

Ergonomic Design and Safety

Ergonomic design is crucial for operator comfort and safety. Exhaustive testing is conducted to optimize the weight, balance, and grip of each rivet gun. Non-slip handles, low vibration levels, and noise reduction features are meticulously engineered to enhance user experience and minimize fatigue. Additionally, rigorous safety inspections are carried out to ensure compliance with industry standards and regulations.

Quality Audits and Certification

Regular quality audits are conducted throughout the manufacturing process to ensure continuous compliance with established standards. Independent testing labs assess the quality of materials, assembly, and performance to provide unbiased verification. Industry certifications, such as ISO 9001, further demonstrate the commitment to quality and reliability.

Continuous Improvement

Quality control is an ongoing process that embraces continuous improvement. Manufacturers regularly gather feedback from customers and distributors to identify areas for optimization. Research and development efforts are focused on developing innovative technologies and refining existing processes to enhance tool performance and durability.

Conclusion

Ensuring reliable results with cordless electric rivet guns requires a multifaceted approach to quality control. From meticulous material selection and assembly to rigorous performance testing and ergonomic design, every aspect is subjected to stringent scrutiny. Independent audits, certifications, and continuous improvement initiatives further reinforce the commitment to excellence. By adhering to these quality control measures, manufacturers empower users with confidence in the performance and durability of their cordless electric rivet guns, enabling them to achieve high-quality results in all applications.

- Company News

- Industry News

- Tag

- Tags

-

What to Look For in a High-Quality Cordless Electric Rivet Gun

In the realm of riveting, where precision meets power, cordless electric rivet guns reign supreme. These indispensable tools empower professionals and DIY enthusiasts alike with the ability to join materials with unmatched efficiency. However, navigating the vast array of options available can be a daunting task. To guide you on this riveting journey, we delve […]

-

How to Select the Best Flat Head Solid Rivet for Your Application

In the realm of fastening solutions, flat head solid rivets stand out as a robust and versatile choice. Understanding how to select the optimal rivet for your specific application is crucial to ensure a reliable and long-lasting joint. This article provides a comprehensive guide to navigating the considerations involved in choosing the best flat head […]

-

Innovative Uses for the Ford Aluminum Rivet Gun in DIY Projects

The Ford Aluminum Rivet Gun is a versatile tool that can be used for a variety of home improvement projects. While it is most commonly used for riveting aluminum, it can also be used to work with other materials such as steel, plastic, and fiberglass. In this article, we will explore some of the innovative […]

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]