How to Handle Different Rivet Types with Your Electric Blind Rivet Gun

Unlock the Power of Rivets: A Guide to Mastering Your Electric Blind Rivet Gun

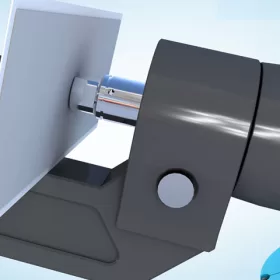

In the realm of fastening, electric blind rivet guns reign supreme, empowering you to effortlessly connect materials with precision and efficiency. However, the mastery of this tool lies not only in its operation but also in understanding the diverse types of rivets it can tame.

Round-Head Rivets: The Sturdy All-Rounders

With their classic cylindrical head, round-head rivets provide a reliable hold in a wide spectrum of applications. Their versatility makes them ideal for joining thin materials, such as sheet metal and plastics.

Countersunk-Head Rivets: Flush and Discreet

Countersunk-head rivets sink below the surface, creating a smooth and aesthetically pleasing finish. This makes them perfect for applications where a seamless appearance is paramount, such as in aircraft interiors or decorative cladding.

Large-Flange Rivets: For Heavy-Duty Connections

When the task demands exceptional strength, large-flange rivets step up to the challenge. Their wide flanges distribute the load more evenly, making them the ultimate choice for connecting thick materials like steel framing and machinery components.

Threaded Rivets: A Versatile Solution

Threaded rivets offer the unique ability to fasten materials without the need for a matching hole. Their threaded shank allows for the installation of screws or bolts, providing additional flexibility and strength in applications such as electrical fixtures and plumbing repairs.

Handling Tips for Different Rivet Types

Round-head rivets: Use a standard nosepiece with a suitable diameter. Ensure the rivet fits snugly into the nosepiece.

Countersunk-head rivets: Select a countersunk nosepiece that matches the rivet head’s angle. Allow space for the rivet head to countersink fully without interfering with the surface.

Large-flange rivets: Employ a large-flange nosepiece specifically designed for these rivets. Grip the nosepiece firmly to prevent the rivet from twisting during installation.

Threaded rivets: Utilize a threaded nosepiece that corresponds to the rivet’s thread size. Align the rivet carefully before setting it to ensure proper engagement.

Mastering the art of using different rivet types with your electric blind rivet gun is the key to unlocking its full potential. By understanding the unique characteristics and handling requirements of each type, you can achieve professional-grade results with ease. Whether you’re tackling home renovations, automotive repairs, or industrial projects, your electric blind rivet gun will become an indispensable tool in your arsenal.

- Company News

- Industry News

- Tag

- Tags

-

What to Look For in a High-Quality Cordless Electric Rivet Gun

In the realm of riveting, where precision meets power, cordless electric rivet guns reign supreme. These indispensable tools empower professionals and DIY enthusiasts alike with the ability to join materials with unmatched efficiency. However, navigating the vast array of options available can be a daunting task. To guide you on this riveting journey, we delve […]

-

How to Select the Best Flat Head Solid Rivet for Your Application

In the realm of fastening solutions, flat head solid rivets stand out as a robust and versatile choice. Understanding how to select the optimal rivet for your specific application is crucial to ensure a reliable and long-lasting joint. This article provides a comprehensive guide to navigating the considerations involved in choosing the best flat head […]

-

Innovative Uses for the Ford Aluminum Rivet Gun in DIY Projects

The Ford Aluminum Rivet Gun is a versatile tool that can be used for a variety of home improvement projects. While it is most commonly used for riveting aluminum, it can also be used to work with other materials such as steel, plastic, and fiberglass. In this article, we will explore some of the innovative […]

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

User-Friendly Features- Making Riveting Easy with Electric Blind Rivet Guns

Electric blind rivet guns are essential tools for industrial applications, providing a convenient and efficient way to fasten materials together. These tools have significantly advanced, incorporating user-friendly features that enhance their functionality and ease of operation. This article explores several key user-friendly features of electric blind rivet guns, highlighting how they simplify and streamline the […]

-

Unleashing Potential- Unlocking the Versatility of a Handheld Rivet Gun

In the realm of construction and fabrication, precision and efficiency reign supreme. Among the indispensable tools that empower craftsmen and DIY enthusiasts alike, the handheld rivet gun stands as a beacon of versatility and innovation. This unassuming device harbors a hidden potential that belies its compact form, offering a plethora of applications that unlock unbounded […]

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]