Eco-Friendly Aspects of Electric Self-Piercing Rivet Guns

Eco-Friendly Aspects of Electric Self-Piercing Rivet Guns: Embracing Sustainability in Industrial Processes

Introduction

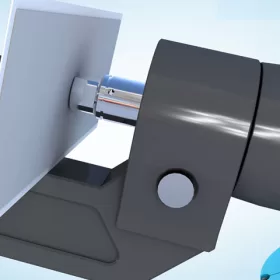

In the realm of industrial advancements, electric self-piercing rivet (ESPR) guns are emerging as game-changers, not only for their efficiency but also their profound environmental implications. By eliminating the need for pre-drilled holes and bulky rivet setting equipment, ESPR guns usher in a wave of eco-friendly practices that reshape the industrial landscape.

Eliminating Wasteful Processes

Traditional riveting methods often necessitate the pre-drilling of holes, a process that generates shavings and debris. ESPR guns, on the other hand, pierce through multiple layers of material simultaneously, creating a permanent joint without the need for pre-drilling. This eliminates the environmental impact associated with waste generation, reducing carbon footprint and conserving scarce resources.

Energy Efficiency

Electric self-piercing rivet guns are powered by electricity, eliminating the need for compressed air or hydraulic systems. This significantly reduces energy consumption compared to traditional methods, contributing to a greener industrial environment. The absence of auxiliary equipment, such as compressors or pumps, also minimizes noise pollution.

Reduced Raw Material Consumption

The use of self-piercing rivets eliminates the need for separate washers and bucking bars. This reduces the amount of raw material required, reducing environmental impact associated with extraction and production. Additionally, the high strength of self-piercing rivets allows for the use of thinner materials, further conserving resources.

Workplace Safety

Electric self-piercing rivet guns minimize vibration and noise levels, creating a safer and more comfortable work environment. The absence of flying debris and sparks also reduces the risk of accidents and workplace injuries.

Case Studies

In the automotive industry, ESPR guns have proven to be a game-changer. By reducing waste, energy consumption, and noise pollution, they have significantly improved production efficiency and environmental sustainability. Similar successes have been reported in various industries, including construction, aerospace, and electronics manufacturing.

Conclusion

Electric self-piercing rivet guns are leading the way in eco-friendly industrial practices. Their ability to eliminate waste, reduce energy consumption, minimize raw material usage, and ensure workplace safety makes them an indispensable tool for businesses seeking a sustainable future. By embracing ESPR technology, industries can significantly reduce their environmental impact and embrace a greener path forward.

- Company News

- Industry News

- Tag

- Tags

-

What to Look For in a High-Quality Cordless Electric Rivet Gun

In the realm of riveting, where precision meets power, cordless electric rivet guns reign supreme. These indispensable tools empower professionals and DIY enthusiasts alike with the ability to join materials with unmatched efficiency. However, navigating the vast array of options available can be a daunting task. To guide you on this riveting journey, we delve […]

-

How to Select the Best Flat Head Solid Rivet for Your Application

In the realm of fastening solutions, flat head solid rivets stand out as a robust and versatile choice. Understanding how to select the optimal rivet for your specific application is crucial to ensure a reliable and long-lasting joint. This article provides a comprehensive guide to navigating the considerations involved in choosing the best flat head […]

-

Innovative Uses for the Ford Aluminum Rivet Gun in DIY Projects

The Ford Aluminum Rivet Gun is a versatile tool that can be used for a variety of home improvement projects. While it is most commonly used for riveting aluminum, it can also be used to work with other materials such as steel, plastic, and fiberglass. In this article, we will explore some of the innovative […]

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

The Latest Innovations in Clinching Tool Design

Explore the latest innovations in clinching tool design, redefining precision, efficiency, and versatility in material joining.

-

The Application and Maintenance of Self-Piercing Rivet Guns

Delve into the applications of self-piercing rivet guns in the automotive and aerospace industries and reveal the essential maintenance practices that ensure their accuracy and efficiency.

-

Rivetless Riveting Gun for Ventilation Duct Projects

The ventilation duct rivetless gun is a tool for riveting ventilation ducts without rivets.

-

Guide to Using Self-Piercing SPR Riveting Gun

In the automotive industry, self-piercing SPR (Self-Piercing Rivet) riveting guns are commonly used for joining metal components in vehicle bodies, including BMW vehicles.

-

Rivet Gun FAQ

Rivet Gun FAQ-SPR

-

Versatile Fastening- Applications of the Handheld Rivet Gun Across Industries

In the realm of fastening, the handheld rivet gun stands as a testament to ingenuity and versatility. Its ability to effortlessly join materials with sheer strength and permanence has revolutionized manufacturing and construction processes, leaving an enduring mark on diverse industries. Aerospace: Where precision and reliability are paramount, the rivet gun shines. In aircraft assembly, […]

-

Time-Saving Tools- Speeding Up Projects with Electric Blind Rivet Guns

In the whirlwind of project deadlines, every minute counts. But what if there was a tool that could dramatically reduce assembly time, giving you an edge in the race against the clock? Enter the electric blind rivet gun: your secret weapon for lightning-fast and effortless riveting. Electric blind rivet guns are the ultimate time-savers for […]

-

Streamlining Fastening- How an Electric Blind Rivet Gun Enhances Efficiency

Introduction In the realm of manufacturing and assembly, fastening plays a crucial role in securing components and ensuring structural integrity. Traditional manual rivet guns, while reliable, are often time-consuming and labor-intensive. The advent of electric blind rivet guns has revolutionized the fastening process, significantly enhancing efficiency and productivity. This article delves into the benefits of […]

-

The Role of Automation in Electric Rivetless Clinching

Electric rivetless clinching (ERC) is a lightweight joining process that eliminates the need for rivets or other fasteners. This can lead to significant cost savings and increased production efficiency. Automation plays a critical role in ERC, enabling high-speed and high-volume production. Automated Feed Systems Automated feed systems are used to accurately position the two workpieces […]

-

Why Choose a Universal Self-Piercing Riveting Gun for Your Projects?

In the realm of construction and fabrication, riveting guns stand as indispensable tools for creating secure and robust connections. Among the various types available, universal self-piercing riveting (SPR) guns have emerged as a game-changer due to their versatility and efficiency. This article will delve into the compelling reasons why choosing a universal self-piercing riveting gun […]

-

Why Choose Stainless Steel Hollow Rivets for Your Projects?

In the world of industrial manufacturing, choosing the right fasteners for your projects is crucial for ensuring longevity and reliability. Among the many options available, stainless steel hollow rivets stand out as a superior choice for a wide range of applications. This article delves into the compelling reasons why stainless steel hollow rivets are the […]

-

Top Trends in Electric Rivetless Clinching Guns

In the realm of fastening technology, electric rivetless clinching guns have emerged as a revolutionary solution for a wide range of industrial applications. These advanced tools offer several преимущества and capabilities, revolutionizing the way businesses approach their fastening needs. Adoption of Brushless Motors Brushless motors have gained significant traction in electric rivetless clinching guns due […]