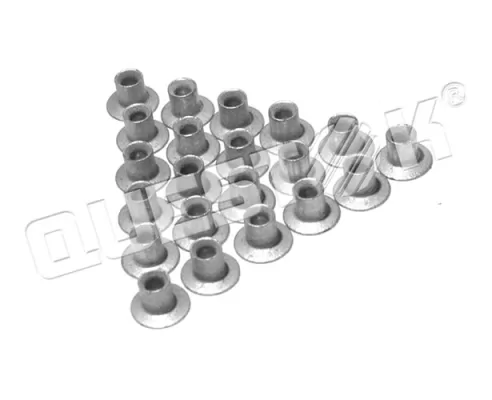

Self-Piercing Rivets (SPR)

In various joining applications involving aluminum or steel materials, self-piercing rivets (SPR) have always been an ideal choice. They can join two or more layers of materials without the need for pre-drilling. Whether for mixed connections or combined joining, self-piercing rivets can be easily managed.

The self-piercing riveting process involves placing a metal layer (aluminum or steel) between a stripper and a die, and through the movement of a punch, the self-piercing rivet is cut through the first layer. Finally, based on the shape of the die, the rivet deforms and spreads into the remaining metal layers. During the fixation of self-piercing rivets, no sparks, smoke, or swarf are generated, eliminating the need for re-painting the workpiece.

Questok’s self-piercing rivets use high-quality materials to securely fasten metal layers, providing durable and safe bonding. Additionally, these self-piercing rivets are coated to prevent cross-contamination and ensure the integrity of the sheet metal joining process.

Our self-piercing rivets can be applied in collision repairs for various automotive brands including BYD, NIO, Ford, BMW, Tesla, Audi, Jaguar, Land Rover, Mercedes-Benz, and more.

Questok offers a range of off-the-shelf universal head SPR rivets, and if you require specialized configurations, we can provide customized solutions as well.